|

|

FluidFlow3

is the first and only integrated software for piping system design,

calculation and optimization that supports liquids, gases, slurries,

2-phase, and non-Newtonian fluids. FluidFlow3

is a truly original software program for the complete hydraulic design,

network analysis, trouble-shooting and optimization of piping systems.

The solution include flows, pressures, temperatures and phase states

through out your piping network.

FluidFlow3

means efficient and accurate modeling for the design of energy

efficient, safe reliable flow systems that are easy to operate and

maintain. A wide variety of industries depend on FluidFlow3 to successfully model new and existing systems, size pipes, select boosters, controllers and other fluid equipment.

All modules have, as standard, the ability to

include heat loss/gain from pipes. Temperature or heat transfer to or

from equipment is also included.

Product Modules

Liquids, Incompressible Fluid Flow

Gas, Compressible Flow

Two Phase Liquid-Gas Flow

Settling Slurries

Non-Newtonian, Non-Settling Slurry Flow

Heat Transfer

Dynamic Analysis & Scripting

__________________________________________________________________________________________________________________

Liquids, Incompressible Fluid Flow

Engineers using FluidFlow3 can determine the

pressure, flow, temperature, and phase state at any point within their

pipe systems. Any type and any size of piping system can be modelled.

Real piping systems often contain many different types of components

and fittings.

FluidFlow3 can model any component (fluid

equipment item) you are likely to come across, these include: boosters

(positive displacement and centrifugal types), valves (including

3-way), flow controllers, pressure sustainers, pressure reducers,

differential pressure controllers, check and non return valves,

orifice plates, reducers & expanders, venturi tubes, inline

nozzles, filters, packed beds, cyclones, centrifuges, labyrinth seals,

pipe coils, relief valves, bursting disks, shell & tube

exchangers, plate exchangers, auto-claves, knock-out pots, as well as

rigorously modelling junctions (tees, wyes, bends, & crosses). For

items not covered by the above you can define your own.

For liquid (incompressible flow) calculations,

FluidFlow3 solves the fundamental conservation equations of mass,

energy, and momentum. Solution of the energy and momentum equations

for an incompressible fluid results in:

- Darcy Weisbach equation

- Bernoulli's principle

Liquid modelling of a LNG storage delivery system

The example opposite shows the main take off line for tanker loading from a LNG storage tank facility.

FluidFlow3 solves continuity, momentum and

energy equations iteratively to arrive at an accurate solution. Phase

states and physical properties are estimated at each point in the

network. Solutions are valid for all flow regimes.

As well as modelling the liquid lines, FluidFlow3 can also model the vapor lines to the external compressor.

|

Gas, Compressible Flow

When a gas flows in a pipe network the gas density, temperature and velocity change as the fluid flows through the network.

A solution approach often used in the literature

is to assume ideal gas laws so that analytical equations for energy,

momentum and continuity equations can be derived. Rather than make

these simplifying assumptions FluidFlow3 uses a calculation procedure

that solves the conservation equations together with an equation of

state for small pressure loss increments. This means FluidFlow3

obtains a rigorous solution.

Available equations of state are:

- Benedict-Webb-Rubin

- Peng-Robinson

- Lee Kesler

Compressor Room Dynamic Scenario

The example opposite shows an air compression and receiver system.

PD Compressors, Air Filters, Recievers, Driers & Relief Systems can all be included in the same model.

Dynamic scenarios are best considered using

script, but of course alternate design scenarios can be considered via

the Input Editing facilities available with all versions and modules.

Gas Results

Consider

the tabular results for the fan discharge pipe as shown opposite.

Along the flowpath the gas expands, the temperature and density

decreases, while the velocity and actual flow increases. This is the

case if no heat transfer occurs, FluidFlow3 can also take heat

transfer considerations into account.

You may also notice that we are displaying 3

volumetric flows in the results table. The first flow refers to the

actual flow at the start of the pipe (remember the actual volumetric

flow increases as gas flows down the pipe), the other flow rates show

volumetric flow with reference to standard and normal conditions.

Gas Chart Results

For

gas flow within a pipe, the pressure and temperature conditions

continuously change. This means that the gas physical properties of

density, viscosity, heat capacity, thermal conductivity, sonic velocity,

etc., change with pipe length.

The curve opposite shows the change in gas

density as we flow down this pipe. This underlines the importance of

using an appropriate calculation method. Imagine the error that would

be introduced if you assumed density was constant.

|

Two Phase Liquid-Gas Flow

The two phase flow module allows two phase

liquid-gas calculations to be accomplished. Two phase flow occurs in

many industrial processes. Examples are petroleum, chemical, nuclear,

refrigeration, space, and geothermal industries.

FluidFlow3 can analyse systems where the vapor

quality changes with pipe position as well as two phase flow where the

vapor quality is fixed.

FluidFlow3 uses a modelling approach for the

pressure loss calculation, this is a hybrid between the rigorous and

empirical methods. By this, we mean, that we use well known empirical

correlations and apply them to a differential pipe length. This allows

for a flash calculation, liquid holdup and flow regime to be

determined for each segment and acknowledges that the pressure loss

per unit length changes as the two phase mixture flows down the pipe.

The available pressure loss relationships that you can use in FluidFlow3 are:

- Friedel: This method is based on the paper

published by Friedel and utilises a two phase multiplier to the liquid

pressure loss calculation.

- Chisholm: Proposed an extensive empirical method (1973), which also uses a two phase multiplier.

- Lockhart-Martinelli: Proposed a separated flow model, but this should only be applied to horizontal flow.

Comparison of the above 3 methods to a recent

two phase database was made by Whalley who made the following

recommendations:(µL/µG) < 1000 and a mass flux of < 2000 kg/m2s

use the Friedel method.

(µL/µG) > 1000 and a mass flux of > 100 kg/m2s use the Chisholm method.

(µL/µG) > 1000 and a mass flux of < 100 kg/m2s use the Lockhart Martinelli method.

If you select the Whalley Criteria in the Calculation Options dialog. FluidFlow3 will select the appropriate method for you.

- More recently Muller Steinhagen and Heck

(2000) made an updated comparison and recommended the MSH correlation

as a better approach, particularly for refrigerants and single

component fluids. This method looses accuracy at high vapor quality.

- One of the first approaches based on flow

regime was made by Beggs Brill. This correlation is applicable to all

pipe orientations. The original method (1973) was extended and

FluidFlow3 uses the extended method. You should probably not use this

method for vertical upflow because it underpredicts pressure loss.

- Drift Flux modelling is accommodated in

FluidFlow3 by using a new correlation published in 2007 [22], this

model is best suited for vertical and inclined pipes.

Two phase input data

The

example opposite shows the Input Editor defined for the supply of a

two phase mixture of steam and water fed directly into a network.

FluidFlow3 will calculate the change in vapor quality as the two phase mixture flows down the pipe.

FluidFlow3 also allows multiphase mixtures to be made via the flowsheet.

Two fluids mixed on a flowsheet

The

flowsheet shows two known flows (one fluid air(2), one fluid

water(1)) combining and being heated via a plate exchanger, then flowing

to a separation vessel (5). The red dot on the Knock Out Pot

(separator) represents the liquid outlet and the yellow dot represents

the vapor outlet.

This is an example of two phase flow with

constant quality. This means that the vapor mass fraction is constant

and there is no mass transfer between the phases. It does not mean

that the pressure loss per unit length is constant or that the

velocity between the two phases is constant. In the first pipe section

after mixing (pipe -6) you can see that the gas superficial velocity

increases from the start to the end of pipe -6. For 60m of pipe -6,

the total pressure loss is 145997 Pa, but the friction loss is 144529

Pa. Since the pipe is horizontal the difference is the acceleration

loss.

Pipeline flow pattern map for two phase flow

The

horizontal flow pattern map for the Beggs and Brill method is shown

opposite. This correlation is applicable to the entire range of pipe

inclination angles, although it usually underpredicts pressure loss

for vertical upward flow.

In this example the predicted flow pattern is in the intermittant region.

Using a mechanistic modelling approach a more accurate model of the flow pattern map can be achieved.

Separation from a boiling mixture

This

example shows a boiling mixture of steam and water flowing through a

pipe network to a vapor-liquid separator. The calculated results have

been exported to Excel. The content of the export can be controlled.

You can download the xls file produced by FluidFlow3 by clicking here.

|

Settling Slurries

Settling slurries comprise a carrier fluid

conveying solid particles. This type of flow has extensive

applications in the mining and mineral processing industries, where

the design of pumped systems must take into account the effect of

solids on pipe friction loss and pump performance.

Simulating the performance of settling slurries

is dependant on the solid density, concentration, particle shape and

size distribution, as well as the properties of the carrier fluid.

Selecting the optimum pipeline velocity is usually the most important

factor in the design and operation of slurry systems. Operating with

velocities too high wastes energy, while operating with velocities too

low can lead to pipeline blackage.

Design methods are highly empirical and FluidFlow3 offers different calculation approaches:

- Wilson-Addie-Sellgren-Clift (WASC)

- Durand-Condolios-Worster

- WASP

Carrier and solids input data

The

example opposite shows the Input Editor defined for the

transportation of 1000 tonne/h of sand at a volume concentration of 30%.

FluidFlow3 will calculate the correct volumetric

flowrate to acheive this requirement. We could have specified flow as

total volumetric, or on a carrier basis only.

Particle size entry requirements depends on the

calculation approach selected. WASC requires d50 and d85, Durand

requires d50 and WASP requires a particle size distribution which the

software allows.

Pump Deration

When

a pump is used to transport a slurry, the prescence of the solid

particles has a significant effect on the performance of the pump. As

the concentration of slurry increases, the head generated by the pump

decreases because of the greater friction losses that occur in the

pump casing.

FluidFlow3 allows you to select the amount of

derating that is applied. This value may be obtained from the pump

supplier, or FluidFlow3 can estimate the deration according to

Hydraulic Institude guidelines or via other text book calculation

methods.

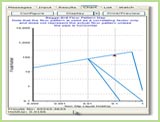

Pipeline system curve for a settling slurry

The

system curve for a settling slurry is different to that of a

Newtonian fluid. The friction loss curve for a nickle ore slurry is

shown opposite. A minimum friction loss value is usually observed at or

near the particle deposit velocity. The most economical velocity is

usually at this minimum point.

The curve shown is asymptotic to the equivalent

water curve at higher velocities, so essentially the slurry flow

calculations are calculations of the "solids effect" of the suspended

solids, i.e., the additional pressure loss due to the suspended solids

over that for the same volumetric flow of the carrier alone.

Usually, because of the application of safety

factors in design methods, pipelines are operated at higher flow

velocities than the economic minimum. There are a series of system

curves, the exact position and shape of each curve depends on the

solid concentration.

Nickle ore delivery system

This example shows a pumped slurry system that has been exported to Excel. The content of the export can be fully controlled.

You can download the xls file produced by FluidFlow3 by clicking here.

Click on the tabs to display the various Excel

pages. Exporting to Excel allows you to customise your reports and

provides an excellent method of communicating the results of a study,

to a client or colleague.

|

Non-Newtonian, Non-Settling Slurry Flow

A non-Newtonian fluid is a liquid whose flow properties are not described by a single constant value of viscosity. Examples of non-Newtonian fluids are: polymer solutions, starch suspensions, paint, blood, food products, and mining suspensions of densely packed particles.

The relation between the shear stress and the strain rate can be either linear or nonlinear. This means that, for fluids exemplifying a nonlinear characteristic, a constant coefficient of viscosity cannot be defined. FluidFlow allows you to describe this relationship of shear-dependent viscosity, according to any of the following rheology models:

- Bingham Plastic

- Power Law

- Herschel-Bulkley

- Casson

Power law modelling of rheology data

The example opposite shows viscometer data for a non-Newtonian fitted to a Power Law relationship.

FluidFlow3 uses different friction factor relationships for each available model, the relationships are valid over all flow regimes.

|

Heat Transfer Capabilities

Heat transfer capabilities are included as

standard within FluidFlow3. At each network element you can select

from any of 3 heat transfer options (pipes have 5 options):

- Ignore Heat Loss/Gain

- Fixed Temperature Change

- Fixed Transfer Rate

- Do Heat Transfer Calculation

- Buried Pipe Calculation

For pipes, the software can also calculate heat loss/gain from the pipe.

Pipes can be insulated with different types of materials using any

thickness. Convection, conduction and radiation losses are calculated.

This means you can use FluidFlow3 to optimize energy use by selecting the economic insulation thickness.

FluidFlow3 can model shell and tube exchangers, plate exchangers, coils and autoclaves.

Pipe heat loss calculation

The example opposite shows the heat loss from a 1 kilometer length of uninsulated pipe.

There are over 300 QA example calculations made before each release of FluidFlow3. This is one of the verification heat transfer calculation examples.

A loss of 1520 kW over the pipe length represents energy wastage of over 1 million dollars per year.

Heat Exchanger Modelling

An example circuit showing 2 heat exchangers with full modelling of both the shell and tubeside. Usually modelling of one side is sufficient.

Several Pressure Loss correlations can be used including: Deleware method, using manufacturers loss data, or using a fixed pressure loss.

With the 2-phase module you can also consider condensors and evaporators.

Larger network showing the design of a computer data centre

This

network, shows how FluidFlow3 is used by a customer to model a chilled

water cooling system in a Data Centre. Modelling of what happens due to

pump failures is also considered in this model.

We have many other customers who model chiller circuits and/or district heating circuits using FluidFlow3.

One customer has sucessfully modelled the

chiller system for Heathrow Airport and another the storage tank heating

system at Europoort. Both networks contain over 5000 pipes and node and

solve in a few minutes.

Buried Pipe Heat Transfer Calculation

In

this example system, we have an offshore natural gas production

platform exporting gas at 80°C via a 100km, 20" buried sea-bed pipeline.

The pipeline is modelled in three sections as follows:

- Pipe segment exposed to air (no coating).

- Pipe segment exposed to sea coated in 3mm polyethylene.

- Pipe segment running along the sea bed coated with 1.5mm PVC and 75mm concrete.

The overall heat transfer coefficients for each

pipe segment have been established from the table of typical values. The

air and sea temperatures used in the example are 10°C and 5°C degrees

respectively.

This heat transfer example is one of many

FluidFlow3 verification examples and the calculated results have been

compared to those available from the software package known as

"Gas/dp" which is discontinued. Note, the results produced by the

"Gas/dp" program were in the past widely accepted as having a

relatively high degree of accuracy.

A PDF summary of the calculated results is available by clicking: "Sea Bed Model Datasheet".

|

Dynamic Analysis & Scripting

Scripting can be an effective tool when you are ready to expand your design capabilities. Considering design scenarios, design optimisation, safety and operating studies are an essential part of achieving quality, well designed flow systems.

Writing a script using

either the Basic or Pascal language enables you to change any network

or element property and watch what will happen. You can see a video

here that shows how 2 control valves adjust to speed changes of a

centrifugal pump.

Today energy conservation should be a vital part of all your designs. Click here to see a video that considers how to minimise energy consumption during operation of a pump station containing 5 pumps.

Flite Software offers Scripting help as a service. To get your project off to a flying start, please contact info@ivisionindia.com directly and we will provide individual advice.

Control Valve Turndown [1m 32s]

Scripting allows you to change any property of any network element and then watch the response of any other property. In this example we change the speed of a pump and watch how flow control valves respond as well as watching the pump duty point adjust on the pump performance chart.

|

Pump Optimisation [40s]

In

this example we will find the optimum pump operating speed if we run 5

pumps in parallel. The optimium speed depends on the number of pumps

operating and can be markedly different.

We will run a script that asks how many pumps we

wish to run. The script solves the system for a series of pump speeds

ranging from the minimum to maximum operating speed. Results are

exported to Excel (Flow, Speed, and Power needed per kg of fluid

pumped).

Finally, the script plots an excel chart, so we can see easily where the optimum speed lies.

|

| |

CONTACT US FOR MORE TECHNICAL INFORMATION AND PRICE QUOTATIONS

|

| |

|

|